Whatever the OSHA safety need, OSTS will come to your location or job site for a one-on-one on-site consultation. OSTS has a variety of services available, including General Industry and Construction industry needs. We can assist with written program development, custom policy and procedure development, facility and site safety inspections, regular and scheduled face-to-face employee safety training in English or Spanish, and most all OSHA regulatory requirements.

Many of our clients rely on OSTS to provide their ongoing, day-to-day, month-to-month safety activity provision and management. We refer to this service as safety Program Management (PM). We customize these PM services to fit applicable OSHA requirements, company size, and client needs.

Our consultants have many years of field experience, allowing for real-world application of OSHA requirements to fit your particular business operation needs.

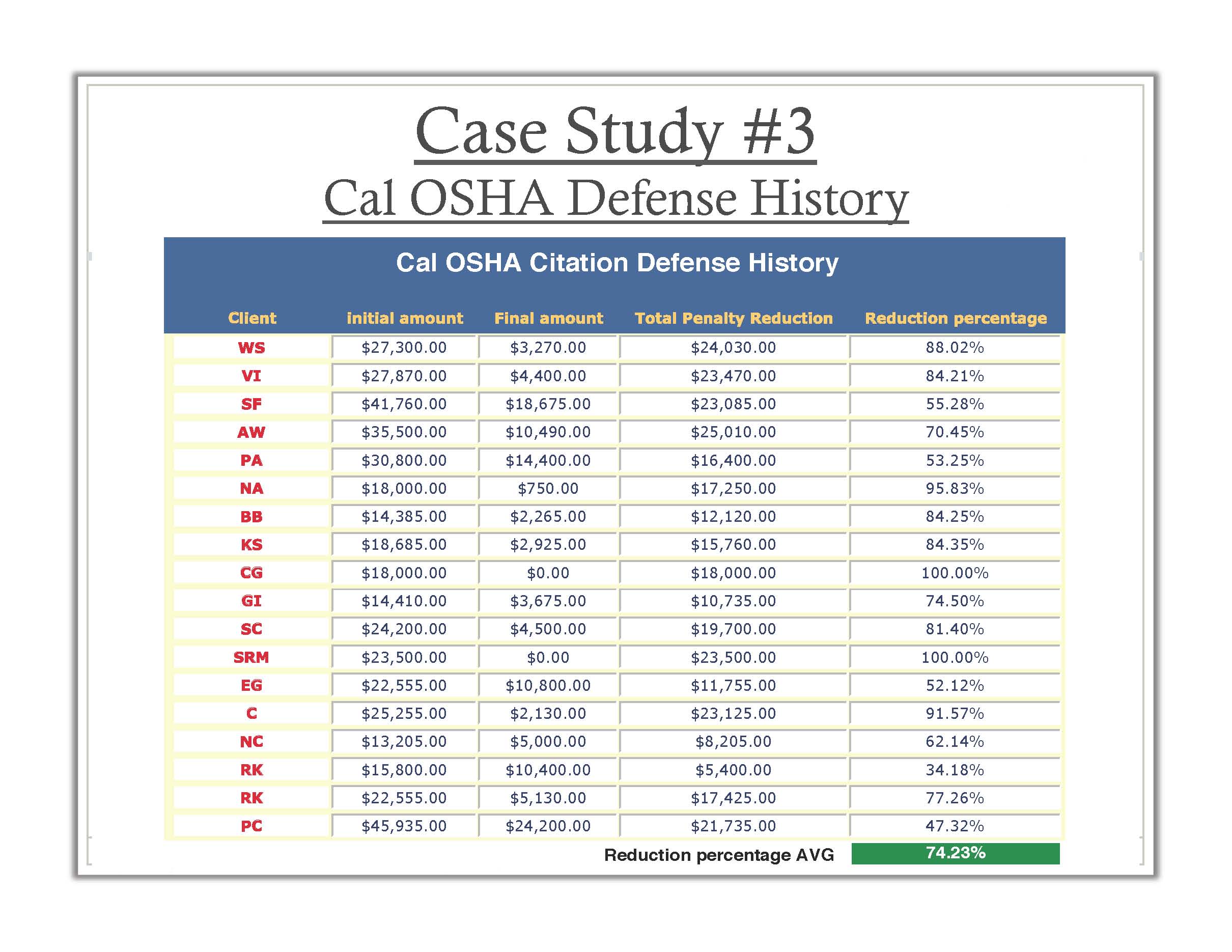

In addition to proactive services, Senior consultants have years of experience dealing with Cal OSHA inspectors, District Managers, and Administrative Law Judges via the OSHA citation appeal defense facilitation. Click below to read about our citation appeal and defense process and defense success.